Quality Policy

Basic Policy: “Implementation of production activities in accordance with the Management Basic Policy, dissemination of safety and quality first, and delivery of high quality products which meet the expectations and needs of the customers”.

For this reason,

- 1. We are placing safety as our top priority, implement adequately the P.D.C.A. (Plan Do Check Act) cycle based on a structured Quality Management System, and continuously improve compliance to requirements as well as the effectiveness of the system.

- 2. Based on the Quality First Policy, each fiscal year, we set quality objectives and implement expansion plans for every department and every hierarchical level as well as their management and education. All employees are encouraged to strive to achieve the quality objectives.

- 3. Our top management, in order to ensure the validity and effectiveness of the Quality Management System, performs periodical reviews, continuously improves the system, and uses resources effectively.

Certification JIS Q9100/9001

Initial Certification Date: 22 August, 2005

Aerospace Quality Management System

- Applied Standard :

- JIS Q 9100:2016 & JIS Q 9001:2015 (ISO 9001:2015)

- Scope of Certification :

- ・Production of Parts for Aircraft Engine and Aircraft Structure

・Production of Parts for Industrial Gas Turbine Engine and Steam Turbine Engine

・Production of Parts for Marine Engine - Non-Applicable Clause(s) :

- 8.3 Design and Development of Products and Services

- Scope Categories:

- 17 Basic metals and fabricated metal products

18 Machinery and equipment

21 Aerospace - Accredited by:

- Defense Structure Improvement Foundation

(BSK System Assessment Center)

- <Central Office specified by SJAC9104-1>

- Certified Site Name : JAPAN AIR TEC Co., Ltd.

Location :

497-1 Yagi, Okubo-cho, Akashi-shi, Hyogo-ken 674-0063 JAPAN

Scope of Certification Applied to the Site :

Same as Scope of Certification

<The Associated Organizations within the Scope of Certification>

Certified Site Name : JAT Co., Ltd. KOBE PLANT

Location :

2-11-3 Murotani, Nishi-ku, Kobe, Hyogo-ken 651-2241 JAPAN

Scope of Certification Applied to the Site :

Same as Scope of Certification

Certified Site Name : JAT Co., Ltd. CHIKUSA PLANT

Location :

886-1 Chikusa, Chikusa-cho, Shisou-shi, Hyogo-ken 671-3201 JAPAN

Scope of Certification Applied to the Site :

Same as Scope of Certification

- Certified Site Name : JAPAN AIR TEC Co., Ltd.

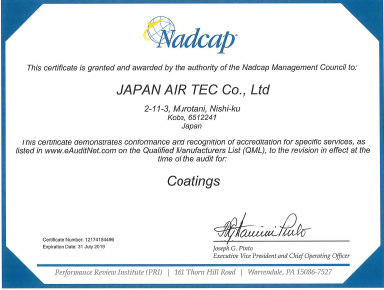

Nadcap Special Process

-

- Scope:

- Welding

- Initial Certification Date:

- 29 February, 2008

- Requirement:

- AC7110/12 - Welder/Welding Operator Qualification

AC7110/13 - Metallographic Evaluation of Welds

AC7110/4 - Resistance Welding

AC7110/5 - Fusion Welding

-

- Scope:

- NonDestructive Testing

- Initial Certification Date:

- 3 July, 2012

- Requirement:

- AC7114 - NonDestructive Testing

AC7114/1 - Liquid Penetrant Inspection

-

- Scope:

- Coatings

- Initial Certification Date:

- 5 May, 2016

- Requirement:

- AC7109 - Coatings

AC7109/1 - Plasma Thermal Spray

AC7109/5 - Coating Evaluations (Laboratory)

MENU